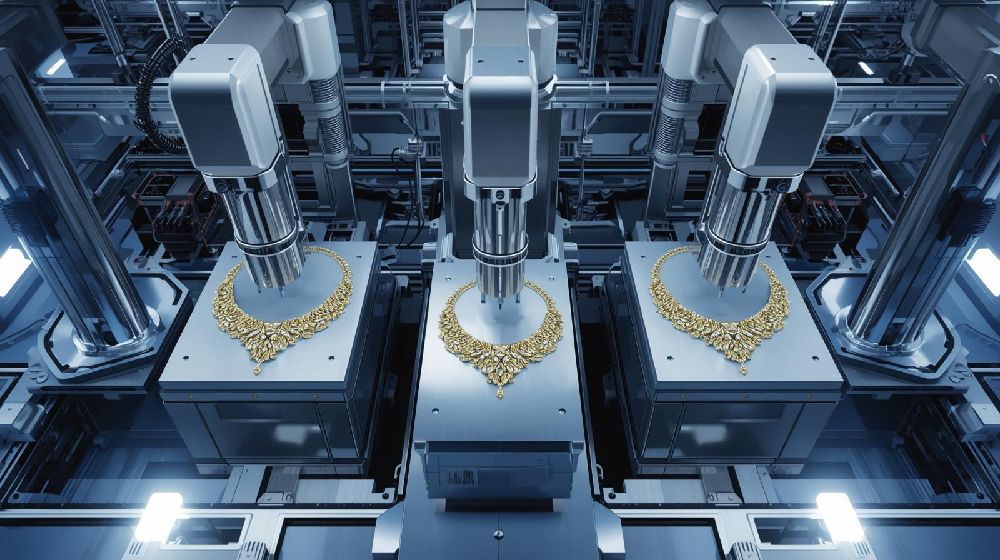

Jewelry has always been a symbol of artistry, heritage, and human touch. For centuries, skilled craftsmen shaped precious metals by hand, guided by experience and intuition. Today, that tradition is being reimagined through digital technology. The jewelry industry is undergoing a powerful transformation—one where craft meets code.

This digital evolution is redefining how jewelry is designed, produced, and perfected.