Jewelry production is entering a new era where tradition meets intelligent technology. As consumer demand grows for precision, consistency, and customization, the jewelry industry is rapidly adopting smart tools and automation to enhance craftsmanship without losing its artistic soul. The future of jewelry production is not about replacing artisans—it’s about empowering them with smarter systems.

The Shift Toward Intelligent Manufacturing

Traditional jewelry manufacturing relied heavily on manual skills, time-intensive processes, and individual expertise. While craftsmanship remains central, smart technologies now assist in achieving higher accuracy, faster production, and scalable quality.

Automation ensures repeatability, while digital intelligence ensures perfection.

Smart Design Tools Driving Innovation

Advanced CAD (Computer-Aided Design) and simulation software allow designers to create highly complex structures with precise measurements. These tools can:

-

Predict weight and material usage

-

Test design strength before production

-

Optimize comfort and wearability

This reduces errors and speeds up product development.

Automation in Manufacturing Processes

Automated systems are transforming production floors through:

-

CNC machines for accurate shaping

-

Laser welding for seamless joints

-

Automated polishing and finishing units

These technologies deliver uniform quality across large batches while minimizing material waste.

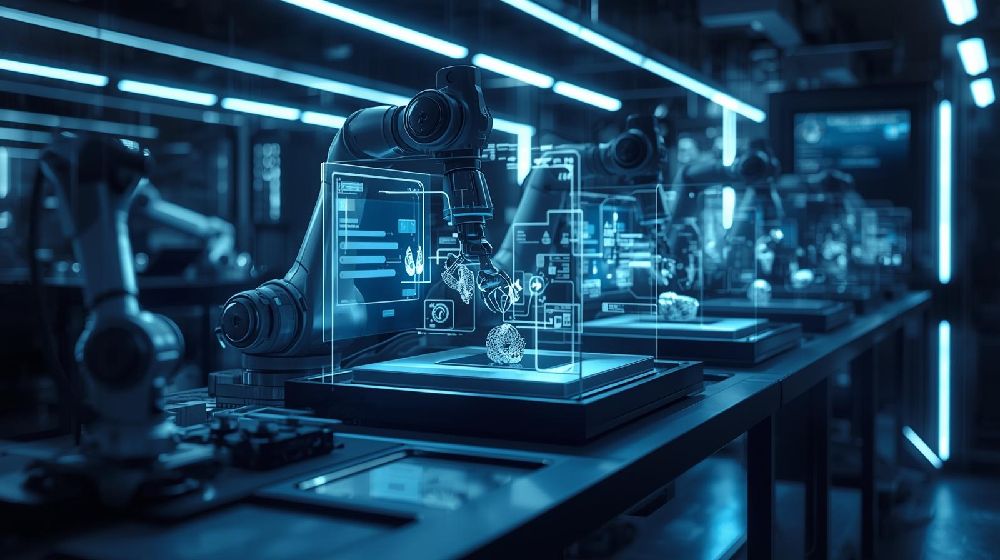

Robotics in Jewelry Making

Robotic arms are increasingly used for repetitive tasks such as cutting, engraving, and polishing. By handling precision-heavy and repetitive work, robots free skilled artisans to focus on detailing, stone setting, and creative finishes.

This collaboration increases efficiency without compromising craftsmanship.

Smart Quality Control Systems

AI-powered inspection tools and digital measurement systems monitor:

-

Thickness consistency

-

Structural integrity

-

Surface finishing

Automated quality control ensures every piece meets strict standards, especially for export and luxury markets.

Customization at Scale

Automation enables mass customization—customers can choose sizes, finishes, and design elements without slowing production. Smart systems instantly adapt designs and production parameters, making personalization faster and more affordable.

Sustainability Through Automation

Smart tools optimize material usage, reduce scrap, and lower energy consumption. Precision manufacturing minimizes rework, supporting environmentally responsible jewelry production without sacrificing quality.

The Role of Skilled Artisans in the Future

Despite automation, human expertise remains irreplaceable. Artisans add the finishing touches, emotional depth, and craftsmanship that machines cannot replicate. Technology enhances their capabilities rather than replacing them.

What the Future Holds

The next phase of jewelry production will include:

-

AI-assisted design recommendations

-

Predictive maintenance for machinery

-

Fully connected smart factories

-

Faster turnaround with consistent luxury quality

These innovations will redefine efficiency, creativity, and customer satisfaction.

Conclusion

The future of jewelry production lies in the harmony between smart tools, automation, and human artistry. By embracing intelligent technology, the jewelry industry can deliver exceptional quality, sustainability, and innovation—ensuring that every piece remains both beautifully crafted and technologically advanced.

Luxury jewelry of the future will not just be handmade—it will be smartly made.